Solar power is one of the most popular forms of alternative energy

today. The concept of harnessing the energy potential of the sun has

led to the development of innovative technologies and energy systems

that have helped reduce the reliance on fossil-fuels that many countries

around the world experience. Efficiency, however, has been a major

problem that has kept solar energy from replacing traditional power

sources. Researchers from the National Renewable Energy Laboratory have

been focusing on improving the efficiency of solar panels, and they may have recently made a breakthrough in this endeavor.

Click Here for a free quote.

Enlarge image

It takes outside-the-box thinking to outsmart the solar spectrum and

set a world record for solar cell efficiency. The solar spectrum has

boundaries and immutable rules. No matter how much solar cell

manufacturers want to bend those rules, they can't.

Enlarge image

It takes outside-the-box thinking to outsmart the solar spectrum and

set a world record for solar cell efficiency. The solar spectrum has

boundaries and immutable rules. No matter how much solar cell

manufacturers want to bend those rules, they can't.

So how can we make a solar cell that has a higher efficiency than the rules allow?

That's the question scientists in the III-V Multijunction Photovoltaics Group at the U.S. Department of Energy's (DOE) National Renewable Energy Laboratory (NREL) faced 15 years ago as they searched for materials they could grow easily that also have the ideal combinations of band gaps for converting photons from the sun into electricity with unprecedented efficiency.

A band gap is an energy that characterizes how a semiconductor material absorbs photons, and how efficiently a solar cell made from that material can extract the useful energy from those photons.

"The ideal band gaps for a solar cell are determined by the solar spectrum," said Daniel Friedman, manager of the NREL III-V Multijunction Photovoltaics Group. "There's no way around that."

But this year, Friedman's team succeeded so spectacularly in bending the rules of the solar spectrum that NREL and its industry partner, Solar Junction, won a coveted R&D 100 award from R&D Magazine for a world-record multijunction solar cell. The three-layered cell, SJ3, converted 43.5% of the energy in sunlight into electrical energy — a rate that has stimulated demand for the cell to be used in concentrator photovoltaic (CPV) arrays for utility-scale energy production.

Last month, that record of 43.5% efficiency at 415 suns was eclipsed with a 44% efficiency at 947 suns. Both records were verified by NREL. This is NREL's third R&D 100 award for advances in ultra-high-efficiency multijunction cells. CPV technology gains efficiency by using low-cost lenses to multiply the sun's intensity, which scientists refer to as numbers of suns.

Friedman says earlier success with multijunction cells — layered semiconductors each optimized to capture different wavelengths of light at their junctions — gave NREL a head start.

The SJ3 cells fit into the market for utility-scale CPV projects. They're designed for application under sunlight concentrated to 1,000 times its normal intensity by low-cost lenses that gather the light and direct it at each cell. In regions of clear atmosphere and intense sunlight, such as the U.S. desert Southwest, CPV has outstanding potential for lowest-cost solar electricity. There is enough available sunlight in these areas to supply the electrical energy needs of the entire United States many times over.

Enlarge image

The new solar cells NREL developed had two things going for them — and one big issue.

Enlarge image

The new solar cells NREL developed had two things going for them — and one big issue.

"The good things were that we could make the material very easily, and we did get the band gap and the lattice match that we wanted," Friedman said. "The bad thing was that it wasn't a good solar cell material. It wasn't very good at converting absorbed photons into electrical energy. Materials quality is critical for high-performance solar cells, so this was a big problem."

Still, NREL continued to search for a solution.

"We worked on it for quite a while, and we got to a point where we realized we had to choose between two ways of collecting current from a solar cell," Friedman said. "One way is to let the electrical carriers just diffuse along without the aid of an electric field. That's what you do if you have good material."

If the material isn't good, though, "you have to introduce an electric field to sweep the carriers out before they recombine and are lost," Friedman said.

But to do that, virtually all impurities would have to be removed. And the only way to remove the impurities would be to use a different growth technique.

"It works great, except you always get a certain level of impurities in the material. That's usually not a problem, but it would be an issue for this novel material, with the gallium arsenide diluted with nitrogen," Friedman said.

A different growth technique, molecular beam epitaxy (MBE), is done in such an ultra-high vacuum — 10 to the minus 13 atmospheres — that it can lower the impurities to the point where an electric field can be created in the resulting photovoltaic junction. And that would make the otherwise promising gallium-arsenide-dilute-nitride material work as a solar cell.

"The only problem was that there was no one in the entire world manufacturing solar cells by MBE," Friedman said.

But that was soon to change.

Because Solar Junction was a mix of enthusiastic recent Ph.D.s and experienced hands from outside the established solar cell field, "they weren't tied to the constraints of thinking this couldn't be done, that the only economically viable way to make solar cells was with MOVPE," Friedman said.

The federal lab and the startup got together. Solar Junction won a $3 million DOE/NREL Photovoltaic Technology Incubator contract to develop a commercial multijunction cell using dilute nitrides, and also received more than $30 million of venture-capital funding for this commercialization effort. To see more about NREL's Incubator projects, see the NREL news release.

"So Solar Junction had this good idea. But now they had to prove that you could actually make a high-efficiency solar cell with this," Friedman said. "Otherwise, who cares? People can make a lot of claims, but it's very simple to know whether you have a good solar cell or not — you just measure it."

It didn't take that long, Friedman said. By 2011, NREL had certified a new efficiency record for Solar Junction's SJ3 cell. The cell achieved an efficiency of 43.5% under concentrated sunlight, a significant step beyond the previous multijunction efficiency record of 41.6%, and far beyond the maximum theoretical efficiency of 34% for traditional one-sun single-junction cells.

Click Here for a free quote.

916-624-0808

Serendipitously, if the germanium substrate is retained, it has essentially the ideal band gap of 0.7 eV for a fourth junction, perfect for capturing longer wavelengths of the solar spectrum. That paves the way for a 50%-efficient solar cell in the not-distant future.

The cost to manufacture the SJ3 cell is competitive with that of the industry-standard GaInP/GaAs/Ge cell, according to Solar Junction. Its greater efficiency translates to significant cost-of-energy savings.

According to a report released this fall from IMS Research, the CPV market is forecast to double in 2012 and reach almost 90 megawatts. The World Market for Concentrated PV (CPV) — 2012 predicts installations of CPV will grow rapidly over the next five years to reach 1.2 gigawatts by 2016.

Because of its design and size, SJ3 is an instant plug-in replacement for the standard cell now used by the space and CPV industries. So, for example, if a 40%-efficient cell were replaced with a 44%-efficient cell, this would instantly increase the entire system power output by close to 10%.

"This is really a classic example of NREL developing something and then industry picking it up and running with it and making it a great commercial success," Friedman said. "We started with some very basic materials research. We took it to the point where it made sense for industry to take over and take it to the marketplace."

"We conceived the cell, demonstrated the individual parts, and let the world know about it," Friedman said. "But Solar Junction put all the parts together with record-breaking results, made it work with MBE, and commercialized it at a time when no one else seemed to be interested in or able to do it."

And now, utilities are ordering the SJ3 cells so fast that Solar Junction has depleted its pilot-scale stock and gone into partnership with manufacturer IQE to ramp up to full manufacturing scale.

Click Here for a free quote.

15 years of research pays off

Scientists from the III-V Multijunction Photovoltaics Group with the National Renewable Energy Laboratory have been working on producing high efficiency solar cells for the past 15 years. During this time, researchers have tested a wide array of materials that could be used to create solar cells, many of which produced lackluster results. Recently, however, the team discovered a material that was capable of boosting the efficiency of solar cells to new heights, breaking the current efficiency record for solar energy systems.Award-Winning PV Cell Pushes Efficiency Higher

Enlarge image

Enlarge image

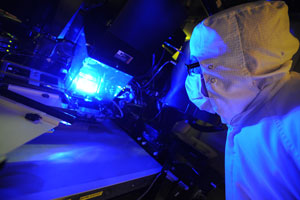

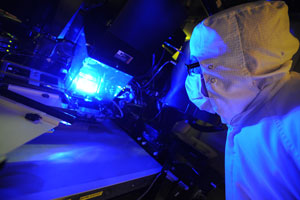

An operator inspects a photolithography tool used to

manufacture high-efficiency Solar Junction concentrator solar cells.

NREL's pioneering multijunction work led to the Solar Junction SJ3 solar

cell with tunable bandgaps, lattice-matched architecture, and

ultra-concentrated tunnel junctions.

Credit: Daniel Derkacs/Solar Junction

So how can we make a solar cell that has a higher efficiency than the rules allow?

That's the question scientists in the III-V Multijunction Photovoltaics Group at the U.S. Department of Energy's (DOE) National Renewable Energy Laboratory (NREL) faced 15 years ago as they searched for materials they could grow easily that also have the ideal combinations of band gaps for converting photons from the sun into electricity with unprecedented efficiency.

A band gap is an energy that characterizes how a semiconductor material absorbs photons, and how efficiently a solar cell made from that material can extract the useful energy from those photons.

"The ideal band gaps for a solar cell are determined by the solar spectrum," said Daniel Friedman, manager of the NREL III-V Multijunction Photovoltaics Group. "There's no way around that."

But this year, Friedman's team succeeded so spectacularly in bending the rules of the solar spectrum that NREL and its industry partner, Solar Junction, won a coveted R&D 100 award from R&D Magazine for a world-record multijunction solar cell. The three-layered cell, SJ3, converted 43.5% of the energy in sunlight into electrical energy — a rate that has stimulated demand for the cell to be used in concentrator photovoltaic (CPV) arrays for utility-scale energy production.

Last month, that record of 43.5% efficiency at 415 suns was eclipsed with a 44% efficiency at 947 suns. Both records were verified by NREL. This is NREL's third R&D 100 award for advances in ultra-high-efficiency multijunction cells. CPV technology gains efficiency by using low-cost lenses to multiply the sun's intensity, which scientists refer to as numbers of suns.

Friedman says earlier success with multijunction cells — layered semiconductors each optimized to capture different wavelengths of light at their junctions — gave NREL a head start.

The SJ3 cells fit into the market for utility-scale CPV projects. They're designed for application under sunlight concentrated to 1,000 times its normal intensity by low-cost lenses that gather the light and direct it at each cell. In regions of clear atmosphere and intense sunlight, such as the U.S. desert Southwest, CPV has outstanding potential for lowest-cost solar electricity. There is enough available sunlight in these areas to supply the electrical energy needs of the entire United States many times over.

Bending Material to the Band Gaps on the Solar Spectrum

Sunlight is made up of photons of a wide range of energies from roughly zero to four electron volts (eV). This broad range of energies presents a fundamental challenge to conventional solar cells, which have a single photovoltaic junction with a single characteristic band gap energy.Good Band Gaps, but Not So Good Solar Material

Enlarge image

Enlarge image

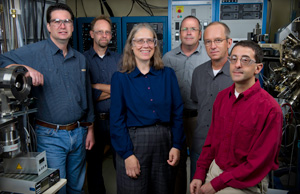

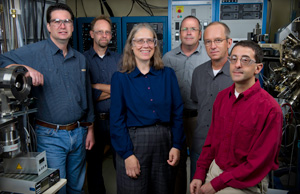

The NREL team that shared the 2012 R&D 100 award

for the world-record SJ3 multijunction solar cell include, from left,

Aaron Ptak, John Geisz, Sarah Kurtz, Brian Keyes, Bob Reedy, and Daniel

Friedman; unpictured team members are Jerry Olson and Steve Johnston.

Credit: Dennis Schroeder / NREL

"The good things were that we could make the material very easily, and we did get the band gap and the lattice match that we wanted," Friedman said. "The bad thing was that it wasn't a good solar cell material. It wasn't very good at converting absorbed photons into electrical energy. Materials quality is critical for high-performance solar cells, so this was a big problem."

Still, NREL continued to search for a solution.

"We worked on it for quite a while, and we got to a point where we realized we had to choose between two ways of collecting current from a solar cell," Friedman said. "One way is to let the electrical carriers just diffuse along without the aid of an electric field. That's what you do if you have good material."

If the material isn't good, though, "you have to introduce an electric field to sweep the carriers out before they recombine and are lost," Friedman said.

But to do that, virtually all impurities would have to be removed. And the only way to remove the impurities would be to use a different growth technique.

Using Molecular Beam Epitaxy to Virtually Eliminate Impurities

Solar cells are typically grown using metalorganic vapor-phase epitaxy, or MOVPE."It works great, except you always get a certain level of impurities in the material. That's usually not a problem, but it would be an issue for this novel material, with the gallium arsenide diluted with nitrogen," Friedman said.

A different growth technique, molecular beam epitaxy (MBE), is done in such an ultra-high vacuum — 10 to the minus 13 atmospheres — that it can lower the impurities to the point where an electric field can be created in the resulting photovoltaic junction. And that would make the otherwise promising gallium-arsenide-dilute-nitride material work as a solar cell.

"The only problem was that there was no one in the entire world manufacturing solar cells by MBE," Friedman said.

But that was soon to change.

Partnering with a Startup out of Stanford University: Solar Junction

A Stanford University research group with expertise in the use of MBE for other electronic devices saw an opportunity, and around 2007, they spun out a startup company they named Solar Junction.Because Solar Junction was a mix of enthusiastic recent Ph.D.s and experienced hands from outside the established solar cell field, "they weren't tied to the constraints of thinking this couldn't be done, that the only economically viable way to make solar cells was with MOVPE," Friedman said.

The federal lab and the startup got together. Solar Junction won a $3 million DOE/NREL Photovoltaic Technology Incubator contract to develop a commercial multijunction cell using dilute nitrides, and also received more than $30 million of venture-capital funding for this commercialization effort. To see more about NREL's Incubator projects, see the NREL news release.

"So Solar Junction had this good idea. But now they had to prove that you could actually make a high-efficiency solar cell with this," Friedman said. "Otherwise, who cares? People can make a lot of claims, but it's very simple to know whether you have a good solar cell or not — you just measure it."

It didn't take that long, Friedman said. By 2011, NREL had certified a new efficiency record for Solar Junction's SJ3 cell. The cell achieved an efficiency of 43.5% under concentrated sunlight, a significant step beyond the previous multijunction efficiency record of 41.6%, and far beyond the maximum theoretical efficiency of 34% for traditional one-sun single-junction cells.

Click Here for a free quote.

916-624-0808

Dilute-Nitride Junction Eliminates Need for Heavy Germanium Layer

With the new dilute-nitride junction, the germanium layer, which constitutes about 90% of the weight of the cell, is no longer needed. That may not be a big deal when it's part of a huge fixed utility-scale array. But when solar cells are used to power satellites, reduction in weight means a smaller rocket is needed to launch into space, potentially reducing costs significantly. The lighter weight is also essential for the military, which is increasingly asking soldiers to carry backpacks that include solar devices to power electronics.Serendipitously, if the germanium substrate is retained, it has essentially the ideal band gap of 0.7 eV for a fourth junction, perfect for capturing longer wavelengths of the solar spectrum. That paves the way for a 50%-efficient solar cell in the not-distant future.

The cost to manufacture the SJ3 cell is competitive with that of the industry-standard GaInP/GaAs/Ge cell, according to Solar Junction. Its greater efficiency translates to significant cost-of-energy savings.

According to a report released this fall from IMS Research, the CPV market is forecast to double in 2012 and reach almost 90 megawatts. The World Market for Concentrated PV (CPV) — 2012 predicts installations of CPV will grow rapidly over the next five years to reach 1.2 gigawatts by 2016.

Because of its design and size, SJ3 is an instant plug-in replacement for the standard cell now used by the space and CPV industries. So, for example, if a 40%-efficient cell were replaced with a 44%-efficient cell, this would instantly increase the entire system power output by close to 10%.

"This is really a classic example of NREL developing something and then industry picking it up and running with it and making it a great commercial success," Friedman said. "We started with some very basic materials research. We took it to the point where it made sense for industry to take over and take it to the marketplace."

"We conceived the cell, demonstrated the individual parts, and let the world know about it," Friedman said. "But Solar Junction put all the parts together with record-breaking results, made it work with MBE, and commercialized it at a time when no one else seemed to be interested in or able to do it."

And now, utilities are ordering the SJ3 cells so fast that Solar Junction has depleted its pilot-scale stock and gone into partnership with manufacturer IQE to ramp up to full manufacturing scale.

Simple trick to cut your power bill up to 75%:

ReplyDeleteWant to know how to easily produce all of the green energy you could ever want right at home?

And you’ll be able to make your home completely immune from power failures, blackouts, and energy grid outages…

so even if everyone else in your area (or even the whole country) loses power…you won’t.

HERE'S HOW: DIY HOME ENERGY